What are the primary ingredients that go into making a hot melt adhesive that is resistant to high t

Due to the fact that polyamide resin is used as the primary matrix in the production of high temperature resistant hot melt adhesive, this type of adhesive is also known as polyamide hot melt adhesive. Polyamide resin is a linear thermoplastic resin that possesses a large number of amide groups that are repeated along the main chain of the molecule. When compared to other thermoplastic resins, this one is distinguished by the fact that, regardless of whether it is heated or cooled, the melting and curing processes of the resin both take place within the same limited temperature range. What are the primary ingredients that go into making a hot melt adhesive that is resistant to high temperatures?.

Because of this property, the polyamide hot-melt adhesive is able to rapidly solidify after being heated, melted, and coated following its application during the construction process. Additionally, it is able to have good bonding properties at temperatures that are close to the point at which it begins to soften.

It is possible for the hydrogen on the amide group of the polyamide resin to combine with the electron-donating carbonyl group on another amide group segment to form a strong hydrogen bond. Because this raises the melting point of the resin, cn-hma.com the polyamide has excellent flexibility, oil resistance, and bonding properties. These characteristics improve as the molecular weight of the resin moves in the opposite direction. Polyamide hot melt adhesives have a higher softening point and consequently better heat resistance than ethylene-vinyl acetate copolymer hot melt adhesives. This is because polyamide has a higher molecular weight.

In most cases, the molecular weight of the polyamide resin that is used as the matrix of the high temperature resistant hot melt adhesive falls somewhere between 1000 and 9000. The polyamide resin that is used as the matrix of hot melt adhesive is obtained primarily through the polycondensation reaction of dimer of unsaturated fatty acid and diamine. This reaction is described as a polycondensation. When making polyamide resins, different diamines are chosen to use. As a result, the resulting resins have distinct differences in their molecular weights and, as a consequence, their melting points. The technique of combining ethylenediamine and hexanediamine is the one that is utilized more frequently.

Why do hot melt adhesives have such poor adhesion? What are the primary contributing factors?

1. The use of the hot melt adhesive requires that it be applied in accordance with the type of material.In the event that the incorrect type of hot melt adhesive is chosen, the material in question will not be able to be bonded;

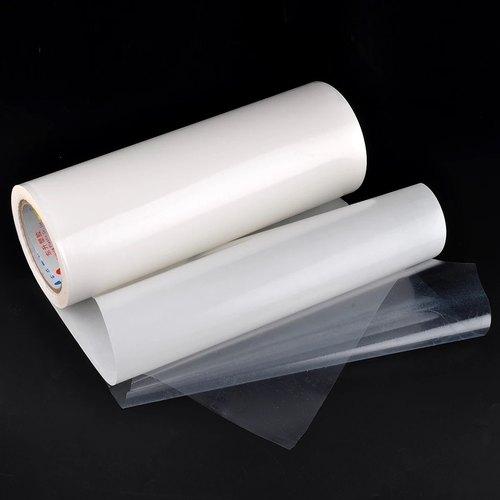

2. The temperature at which the melting occurs is insufficient.When bonding, the hot melt adhesive does not exert enough pressure on the adherend after melting; when bonding, there is not enough time for the hot melt adhesive to harden; 5. The surface of pes hot melt double sided adhesive lining the object to be bonded has not been cleaned, and there is dust or impurities that affect the bonding; 6. The temperature is not high enough, so the hot melt adhesive does not fully melt, and the connection cannot be produced well; 7.

The adhesive known as "hot melt" is a type of plastic adhesive. Within a certain temperature range, a change in temperature will cause a change in its physical state, but it will not affect the chemical properties of the substance in any way. It does not have any flavor, is safe to consume, and is a chemical product that is good for the environment. Because users of hot melt adhesives lack an in-depth understanding of hot melt adhesives, they frequently run into various problems during the production process. One of these problems is the phenomenon of non-stick glue, which occurs during the use of hot melt adhesives. The following is an explanation of how the hot melt adhesive film bonding strength of hot melt adhesive can be improved.

1. Reduce the roughness of the surface

The roughening of the surface is beneficial to improve the degree of infiltration of the hot melt adhesive liquid to the surface and increase the contact point density between the hot melt adhesive and the adhered material. This is beneficial to improve the bonding strength. When the hot melt adhesive infiltrates the surface of the adhered material well (contact angle 90°), the roughening of the surface is beneficial to improve the degree of infiltration of the hot melt adhesive liquid to the surface.

2. Surface treatment

The surface treatment of the adherend will affect the bonding strength due to the weak boundary layer formed in the adherend by the oxide layer (such as rust), chrome plating layer, phosphating layer, mold release agent, etc. The surface treatment of aluminum and aluminum alloys will also have an effect on the bonding strength due to the same weak boundary layer.It is hoped that aluminum oxide crystals will form on the surface of the aluminum. The surface of naturally oxidized aluminum is quite uneven, and the aluminum oxide layer is quite loose, neither of which is conducive to bonding. The formation of aluminum oxide crystals on the surface of the aluminum is the goal.

3. Penetration

The action of the surrounding atmosphere will frequently result in the bonded joint becoming infiltrated into other low-molecular-weight substances.For instance, when the joint is located in a moist environment or under water, water molecules are able to penetrate the adhesive layer. Additionally, when the polymer adhesive layer is submerged in an organic solvent, solvent molecules are able to penetrate the adhesive layer.The penetration of low molecules into the polymer first causes the adhesive layer to become deformed, and then these molecules enter the interface that exists between the adhesive layer and the adherend, causing the strength of the adhesive layer to decrease and ultimately leading to the breakage of the bond.

4. Migratory Patterns

Due to the poor compatibility of these small molecules with polymer macromolecules, adhesive materials that contain plasticizers are easily able to migrate from the polymer surface or interface. If the migrated small molecules accumulate on the interface, it will hinder the hot melt process.The failure in bonding is due to the bonding that occurs between the glue and the material that is to be adhered.

5. Pressure

Applying pressure to the bonding surface during the bonding process will make it simpler for the hot melt adhesive to fill the holes on the surface of the adherend and will even allow it to flow into deep holes and capillaries, which will reduce the number of bonding defects.When you apply pressure to copa hot melt adhesive web it, it will flow excessively, which will leave you without any glue.Because of this, pressure should be applied when the viscosity is high. This not only encourages the gas on the surface of the adherend to escape, but it also helps reduce the number of pores in the area that is being bonded.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness