How are Oil Rigs Installed?

Oil rigs, also known as offshore drilling platforms, are colossal structures that play a crucial role in extracting oil and gas from beneath the seabed. But how do these behemoths, often weighing hundreds of thousands of tons, end up firmly anchored in the vast ocean?

The installation process of an oil rig is a complex and meticulously planned operation involving several key stages:

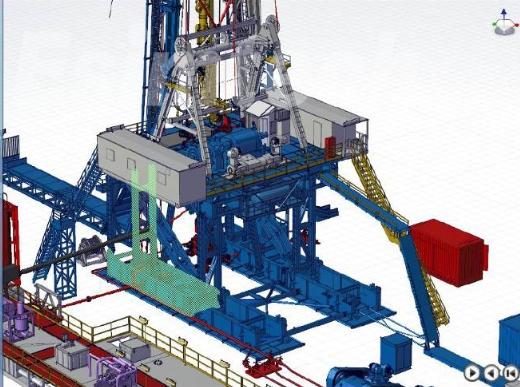

1. Fabrication: The journey begins at a fabrication yard, where the individual components of the rig, from the massive steel jacket to the drilling equipment and living quarters, are meticulously constructed and assembled. This stage can take months or even years, depending on the size and complexity of the rig.

2. Transportation: Once construction is complete, the rig needs to be transported to its designated location at sea. This can be done in two primary ways:

- Floatation: Smaller rigs are often towed to the site by powerful tugboats while floating on their own buoyancy. For larger rigs, specially designed barges are employed to transport them in a semi-submerged state.

- Heavy-lift vessels: Some enormous rigs, particularly those designed for deepwater operations, are transported in sections using specialized heavy-lift vessels. These vessels can lift and transport colossal structures weighing millions of pounds.

3. Foundation Installation: Depending on the type of rig and the water depth, different foundation methods are employed:

- Jackets: For shallow water depths, a steel jacket, essentially a giant latticework structure, is lowered onto the seabed and secured using piles driven deep into the ocean floor.

- Gravity base structures (GBS): These massive concrete or steel structures are prefabricated onshore, then towed to the location, and sunk onto the seabed, relying on their own weight for stability.

- Anchor piles: For deepwater applications, the rig might be anchored to the seabed using several large-diameter piles driven deep into the ocean floor.

4. Topside Installation: Once the foundation is secure, the topside modules, housing the drilling equipment, living quarters, and other essential facilities, are carefully lifted and placed onto the jacket or platform using powerful cranes. This intricate process requires precise planning and coordination to ensure the modules are positioned and secured accurately.

5. Hookup and Commissioning: After all the components are installed, the final stage involves connecting all the piping, electrical systems, and equipment. This critical phase, known as hookup and commissioning, ensures everything functions properly before the rig can begin drilling operations.

The installation of an oil rig is a testament to human ingenuity and engineering prowess. It involves meticulous planning, cutting-edge technology, and the expertise of highly skilled professionals working together to bring these colossal structures to life in the harsh environment of the open ocean.

- Sanat

- Doğa

- El sanatları

- Dans

- İçecekler

- Film

- Kondisyon

- Gıda

- Oyunlar

- Bahçıvanlık

- Sağlık

- Ev

- Edebiyat

- Müzik

- Networking

- Diğer

- Parti

- Din

- Alışveriş

- Spor Dalları

- Tiyatro

- Yaşam