Unveiling the Different Stages of Lube Oil Refining

In the realm of modern machinery and transportation, lubricants play an indispensable role, ensuring smooth operation and preventing wear and tear. These crucial fluids are sourced from crude oil, the lifeblood of the petroleum industry. However, crude oil, in its raw form, is not directly usable as a lubricant. It undergoes a complex and intricate process known as lube oil refining, meticulously transforming it into the high-performance lubricants that power our world.

Stage 1: Desalting

Crude oil, as extracted from the earth's depths, often contains impurities, including water and salts. The initial stage of lube oil refining, aptly named desalting, aims to remove these contaminants. The crude oil is mixed with a desalting agent, typically an emulsifier, which causes the water and salts to form droplets that separate from the oil. This mixture is then subjected to an electrostatic field, which accelerates the droplets towards collection electrodes, effectively removing them from the oil.

Stage 2: Atmospheric Distillation

The desalted crude oil now embarks on a journey through a series of distillation towers, starting with atmospheric distillation. In this stage, the oil is heated to a high temperature under atmospheric pressure, causing it to vaporize. The vapors rise through the tower, where they condense at different heights based on their boiling points. This separation process yields various fractions, including gasoline, kerosene, and light distillates, each with distinct properties and applications.

Stage 3: Vacuum Distillation

Following atmospheric distillation, the heavier fractions, known as vacuum residues, enter the realm of vacuum distillation. In this stage, the pressure is significantly reduced, allowing the heavier components to vaporize at lower temperatures. This process further separates the vacuum residues into lube oil distillates, which serve as the foundation for the final stages of refining.

Stage 4: Solvent Extraction

Solvent extraction employs selective solvents to remove undesirable impurities from the lube oil distillates. These solvents, carefully chosen for their affinity to specific contaminants, are mixed with the distillates, causing the contaminants to dissolve and separate from the oil. The solvent-containing contaminants are then extracted, leaving behind a purified oil fraction.

Stage 5: Hydrotreating

Hydrotreating introduces hydrogen into the refining process, serving as a catalyst for chemical reactions that remove sulfur, nitrogen, and oxygen compounds from the oil. These impurities can lead to corrosion and reduce the oil's performance. By eliminating these contaminants, hydrotreating enhances the oil's stability and improves its antioxidant properties.

Stage 6: Dewaxing

Paraffinic waxes, naturally present in crude oil, can solidify at low temperatures, affecting the oil's viscosity and performance. Dewaxing addresses this issue by selectively removing the waxes from the oil. The oil is chilled to a specific temperature, causing the waxes to crystallize and separate from the liquid oil. These crystallized waxes are then filtered out, leaving behind a wax-free oil with improved low-temperature fluidity.

Stage 7: Blending

The final stage of lube oil refining involves blending the refined oil fractions with additives to achieve the desired performance characteristics. These additives, carefully selected based on the intended application of the lubricant, can enhance properties such as oxidation resistance, wear protection, and viscosity index. The blended oil is then subjected to rigorous quality control tests to ensure it meets the specified standards.

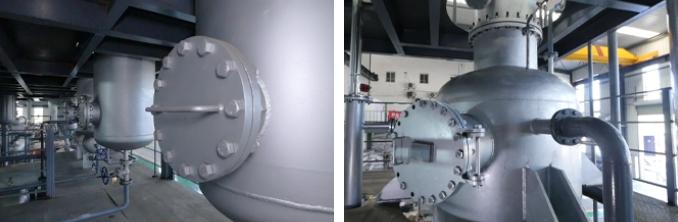

The Lube Oil Refining Plant: Orchestrating the Refining Process

A lube oil refining plant is a complex industrial facility that houses the intricate equipment and processes described above. Each stage of refining is meticulously controlled and monitored to ensure the production of high-quality lubricants. From the initial desalting to the final blending, the lube oil refining plant orchestrates a transformation, converting crude oil into the lubricants that power our engines and machines.

Conclusion

The journey of crude oil to refined lubricants is a testament to human ingenuity and technological advancement. Through the intricate stages of lube oil refining, we transform a raw material into a versatile product that plays a vital role in modern society. As we continue to strive for cleaner and more efficient energy sources, the importance of lube oil refining will only grow, ensuring that our machines continue to operate smoothly and efficiently for years to come

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness